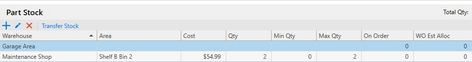

The Part Stock section of Antero allows for inventory levels of parts to be defined. Users can associate parts with the Warehouses where actual quantities are managed. The quantities and defined warehouses allow users to select specific parts to be associated with work orders and part orders as necessary.

Part Stock Details

Important information is stored in the Parts Stock information area. The following fields are highlighted for their importance when working with other sections of Antero.

•Warehouse: Warehouses are the locations or storage areas where parts can be found. Parts can be associated with multiple warehouses allowing for accurate inventory levels to be maintained. Additionally, parts can be ordered to, then used from the specific warehouses associated with each part. Unlimited warehouses can be created and used for parts/materials tracking.

•Area: The Area list field allows users to associate Parts Stock with a defined Stock Location. The Area field is a single piece of data that can be used to describe the location of a part.

•Unit Cost: The Cost is the current price of the Part according to the Suppliers documentation. This cost will be pulled when the part is ordered from the supplier in the Ordering section.

Note: When ordering in bulk, the cost field will be determined by taking the number defined in the bulk units and multiplying the per unit cost.

Example: Here is an example of how cost is calculated for bulk. If order in bulk is defined to order a box of 10 units, a single box ordered will take the cost of the 10 units and multiple it by the Unit Cost. Unit cost is defined as $2.00 for a light bulb. If the bulk units is defined as 10, the order will be $20.00 for a single box of light bulbs.

•Quantity: The Quantity is the current quantity on hand for a specific parts stock location. Enter the beginning quantity on hand to allow Antero to add or delete quantities in the future based on usage within the Work Orders, Parts Orders, and Consumables sections.

•Min Qty: The Min Qty (minimum quantity) allows users to specify the quantity at which they should be prompted to reorder the selected part. A list of parts to be reordered is available in the Reorder List.

•Max Qty: The Max Qty (maximum quantity) allows users to specify the quantity to which they should restock the selected part. If a part is to be reordered via the Min Qty, the Max Qty will be a suggestion of the total quantity to be reordered.